Component Selection and Bill of Materials:

SMD devices where used for smaller sizer, 0603 resistors are a good compromise between easy hand solderability and small size.Texas Instruments LME49723 audio dual operational amplifier was chosen as a good compromise between low distortion, quality, cost, size, nice SOIC packaging and high power supply voltage.

I particularly like TI website for its quick and easy selection of components by means of a parameters table and a large choice of components.

Even though I am a big fan of MLCC (multilayer ceramic capacitors) I read in a series of articles in EDN website (Signal distortion from high-K ceramic capacitors and the follow-up More about understanding the distortion mechanism of high-K MLCCs) that film capacitors are better suited for audio applications since they are more linear in its frequency response and have less harmonic distortion than ceramic capacitors. MLCC capacitors experience large changes in capacitance as the voltage across them changes, which can result in harmonic distortion. So I decided to use film capacitors everywhere where the capacitor value was key to filtering the audio signal.

But I still used MLCC for signal bypassing and power supply decoupling.

The BoM was created in the Mouser website, with a huge selection of components and hardware

This is the link to he whole Bill of Materials on the Mouser website:

Input Preamp and Output Amp Schematics (page 1)

Each opamp stage is based in the aforementioned LME49723 device consisting of two opamps.

In the first opamp stage, zener diodes are used to clip signal levels. A 6.2V zener diode BZX84C6V2LT1G is used in the positive cycles and a 4.3V zener diode BZX84C4V3LT1G is used in the negative cycles.

After the first opamp stage a Schottky diode BAT54 in series with a 470k resistor is used for soft clipping, this provides a clipping closer to germanium diodes.

On the second opamp stage there is a feedback branch with a NPN transistor (MMBT2907ALT1SMD) which has its base biased at 1.65V, a TI LM4041CIDBZ shunt voltage reference was used. Another feedback branch uses a 2.7V zener diode BZX84C2V7LT1G in series with a diode MMBD4148 and a 470ohm resistor for clipping negative cycles. A third branch used another 2.7V in series with a higher 10K resistor for soft clipping of positive cycles.

The third opamp stage is just a follower to send the signal to an external effect circuit and to the output amp section. The return is also input to this stage.

An equivalent circuit to the VOX AC30 bass/treble equalizer is placed at the input of the output amp section. The equalization switch adds a deeper mid notch when activated.

The first opamp stage of the output amp adds harder clipping with two silicon diodes MMBD4148 in parallel for clipping both positive and negative cycles. And also a schottky diode in series with a 47 ohm resistor that provides a kind of germanum diode clipping in the negative cycles.

The second opamp stage adds additional clipping in both cycles by using silicon diodes MMBD4148.

A log 100K potentiometer provides volume level control of the output amp.

The forth opamp is a double follower that sends the signal to the speaker simulator and the Line out connector.

Speaker Emulator and Headphone Amplifier Schematics (page 2)

The second page of schematics shows the speaker emulator circuit based on four Sallen-Key low-pass filter sections to provide a frequency response similar to that of a 12'' speaker like Celestion Vintage 30, as shown in a previous post. This filter enhances considerably frequencies around 2.5 kHz.A log 100K potentiometer provides speaker emulator volume level.

A switch selects Line out signal from the speaker emulator output or the output amp to be connected to an external guitar amplifier.

The headphone input is always selected from the speaker emulator output.

The headphone amplifier used is a TI TPA6111A2D 150 mW stereo headphone amplifier in a SOIC-8 device connected to a 3.5 mm mini-jack.

25W Class D Amplifier, mounting holes, fiducials (page 3)

The third page of the schematics shows the 8ohm speaker amplifier based on a very efficient (94%) 25W Class-D amplifier TI TPA3112D1PWP with less than 0.1% THD+N from a +24V supply.The high efficiency of this new class-D amplifiers allows a relatively high power output of 25W without the need of a heatsink on a small HTSSOP 28-pin device which considerably reduces PCB layout size. Special careful must be taken with the design of the central pad connected to the ground plane by numerous vias to allow proper heat dissipation.

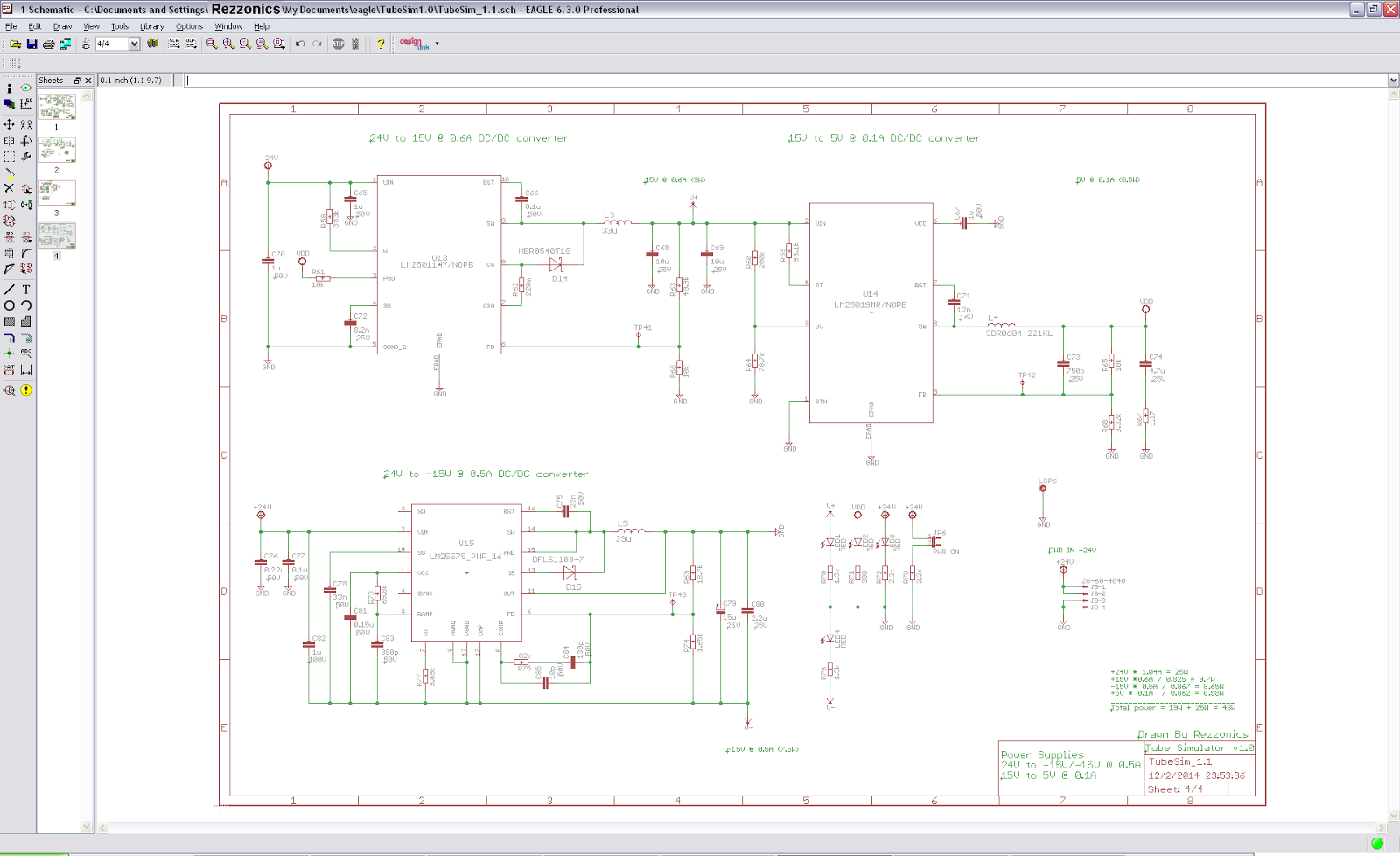

Power Supplies (page 4):

An independent switching power supply module converts 220V AC@50Hz into +24V DC. A Murata MVAD040-24 40W (23 euros) open switching power supply module is used. The module has its own PCB and is mounted inside the box with standoffs and screws.The main PCB is then powered at 24VDC. This is the highest voltage used for output class-D 25W power amplifier.

From 24V, discrete switching regulators generate +15V and +15V to power the operational amplifiers.

From +15V a discrete switching regulator generates +5V to power the headphone amplifier.

The maximun power consumption budget is distributed as follows:

+24V @ 1.1A = 25W for the class D speaker power amplifier (94% efficiency)

+24V to +15V @ 0.6A = 9W for the positive rail of opamps

+15V to +5V @ 0.1A = 0.5W for the headphone amplifier

24V to -15V @ 0.5A = 7.5W for the negative rail of opamps

Total maximum power consumption is 40W

All discrete DC-DC converters have been designed using TI Webench Design Center, a very useful tool for designing power supplies that allows optimizing BoM cost, footprint and efficiency.

The Webench tool generates the whole BoM and it even allows to export schematics and layout to several of the most common CAD applications including Eagle. Sometimes the results are not very good but at least the footprint of mos common components can be created.

Most regulators are based on step-down or buck topology using integrated controllers (power switching MOSFET integrated in the controller device) except for the +24V to -15V that uses inverting buck-boost topology.

The +24 to +15V DC-DC converter is based on TI LM25011 step-down regulator.

The +24V to -15V DC-DC converter is based on TI LM25575 step-down regulator in inverting buck topology

The +15V to +5V DC-DC converter is based on TI LM25019 step-down regulator

This schematic page also includes external Power-on LED and internal SMD power-on LEDs for every power rail: +24V, +15V, -15V and +5V as well as 24VDC power in connector to main PCB from external AC-DC power supply